Cherepovets Steel Mill PAO “SEVERSTAL” - Ленгипромез

Main menu:

- Reference List

- Metallurgy of Leningrad

- Foreign Projects

- PAO “Severstal”

- “Ural Steel” LLC

- “Severgal” CJSC

- “NLMK” OJSC

- “PC&T” Ltd

- MP “ Electrostal” OJSC

- “CPRP” OJSC

- “Izhora Pipe Mill” CJSC

- “INTERCOS – IV” CJSC

- JSC “KCSP”

- “MECHEL” CJSC

- FSUE “CRISM “Prometey”

- FSUE “KSRC”

- “EVRAZ NTMP” OJSC

- Sanatorium “Metallurg”

- Pre-design studies

Cherepovets Steel Mill PAO “SEVERSTAL”

PROGECTS

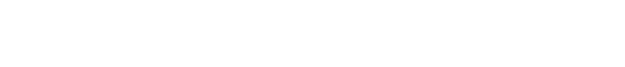

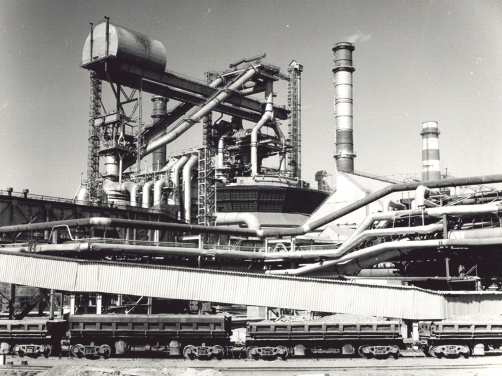

Ironmaking Plant, 1957

Coke Oven Battery, 1957

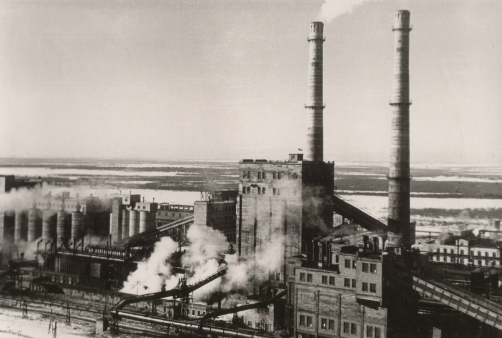

BOF Shop.

Melting department

Melting department

The question of creation of a metallurgical base in the European North area of Russia Cherepovets , Lodeinoye Pole, Aniensky Bridge Leningrad – Murmansk research expedition under leadership of Academician I.P. Bardin recommended in the pre–war years to choose Cherepovets

On June 20, 1940 I.V. Stalin and V.M. Molotov have signed Decree № 1066 – 417с “On establishment of a metallurgical base in the north – west area of the USSR

In spite of secrecy of the started works, on September 21, 1940, some information appeared in the newspaper “The Industry” announcing that “Gipromez” began designing of a new metallurgical plant to-be-constructed in Cherepovets

In the course of several years, till the Great Patriotic War, the disputes about the location of this north – west steel works have been continued.

On January 27, 1944 the artillery salute announced the liberation of Leningrad

On 16 – 18 April, 1946 the Soviet for study of the productive forces at the Academy of Sciences of the USSR has heard the report of the Leningrad – Murmansk research expedition and concluded that “the principal issues of the source of raw materials and the fuel resources for the north – west metallurgy were investigated and prepared in such a degree that allows to start the designing of the Cherepovets Steel Mill and simultaneously the preliminary and civil engineering works on site”.

On December 30, 1947 I.V. Stalin has signed a Decree “On construction of the Cherepovets Steel Mill and of ore and raw materials base for it”.

The designers and the earliest builders have overcome many difficulties, and on August 24, 1955 the fire–spitting hot-metal stream appeared from the Blast Furnace marking the birth of the Cherepovets Steel Mill.

Sheet–Rolling Plant № 2

2000 mm Wide–Strip Hot Rolling Mill

2000 mm Wide–Strip Hot Rolling Mill

| May of 1954 | TPP – TBS |

| February of 1956 | Coke Oven and By-Product Plant |

| July of 1955 | Sinter Plant |

| August of 1955 | Ironmaking Plant |

| May of 1958 | Open–Hearth Plant |

| October of 1969 | Electric Arc Furnace Shop |

| November of 1959 | Sheet–Rolling Plant № 1 |

| 1973 | Sheet–Rolling Plant № 2. Sheet dressing |

| April of 1975 | |

| December of 1961 | Bar–Rolling Plant |

| May of 1962 | Formed Sections Department |

| Consumer goods: | |

| October of 1963 | Mass Consumption Goods Shop |

| October of 1973 | Enamel Kitchen Utensils Shop |

| November of 1980 | Acid Converter Shop |

| April of 1986 | Blast Furnace № 5 |

“Lengipromez” started and continues designing of the Cherepovets Steel Mill units and facilities. The staff of “Lengipromez” has prepared in fruitful cooperation with their colleagues from the specialized design institutes the designs of the shops and departments which are by their parameters at the front lines of the ferrous metallurgy in the country.

Revamping

of Blast Furnace № 4

Ironmaking Plant

Hot–metal sampling

Hot–metal sampling

Ironmaking Plant

Iron tapping

Iron tapping

Blast Furnace № 4 has been constructed

according to the “Lengipromez” design. The Blast Furnace № 4 blowing–in took

place on March 27, 1969. The first iron tapping was accomplished on March 29,

1969. Nine months later the Blast Furnace came up to its full rated capacity,

and due to this the Ironmaking Plant output was increased by 75 %.

Blast Furnace № 4 with a working volume of 2700 m3 had an

annual output capacity of 1800 thou. tons of hot metal or 5000 tons daily. At

the time of its commissioning it was the largest blast furnace unit not only in

the USSR but all over the Europe , as well. After Cherepovets

the blast furnaces of the same capacity have been erected in Krivoi

Rog , Nizhni Tagil, Temirtau

But the

highest effective volume utilization factor was achieved just at Blast Furnace №

4 at the Cherepovets

In the period of business recession in the

nineties, in December of 1995, Blast Furnace № 4 was stopped, and only on

December 18, 2005 it was put into operation again after the complete revamping.

At its commissioning the furnace was given a name “Vologzhanka”.

“Lengipromez” was entrusted to prepare the

design documents.

During the revamping period the updating of the

blast furnace complex equipment has been implemented. In the result of

revamping the Blast Furnace № 4 capacity was increased from 1800 thou. tpy to

2200 thou. tpy of iron. The adverse environmental impact was considerably

reduced due to some technical innovations, as well.

Today Blast Furnace № 4 is producing almost one

third of the total Cherepovets

At blowing–in of Blast Furnace № 4 on December 25, 2005

Ironmaking Plant

Monitoring of iron smelting process

Monitoring of iron smelting process

Blast Furnace № 4 command room

Basic indicators of BF № 4 operation

| Working volume, m3 | 2700 |

| Oxygen enrichment, % | 30.91 |

| Hot blast temperature, ˚C | 1194 |

| Natural gas rate, m3/per 1 ton of hot metal | 130 |

| Top gas temperature, ˚C | 134 |

| Top gas pressure, atm gauge | 1.84 |

| Effective volume utilization factor (design/actual) | 0.38/0.33 |

| Output, t/daily (design/actual) | 7200/8400 |

Blast Furnace № 4

Cast house of Blast Furnace № 4

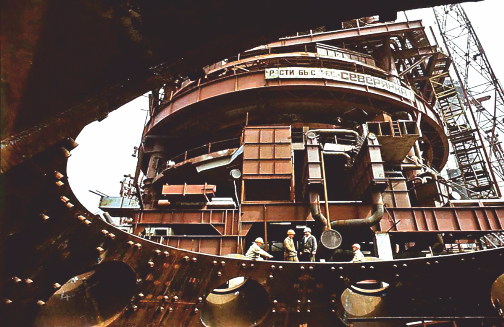

Revamping of Blast Furnace № 5

Blast Furnace № 5

The largest blast furnace in Europe

The largest blast furnace in Europe

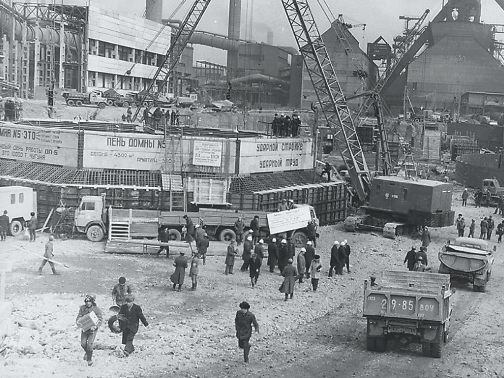

Construction of Blast Furnace № 5, 1982

Blast Furnace № 5 (“Severyanka”)

was blown–in on April 12, 1986, the first iron was tapped on April 13, 1986.

The construction of Blast Furnace № 5 was declared to be the All–Union Komsomol

Building Project.

In designing of almost 250

facilities of the blast furnace complex about 40 design institutes have taken

part, and the general designer – “Lengipromez” was among them. More than 13

thousand builders and erectors were engaged in the blast furnace construction.

In the course of construction

more than 160 thousand tons of steel structures were erected, 78 thousand tons

of equipment were installed, over 200 thousand cubic meters of precast

reinforced concrete were placed, 520 thousand cubic meters of cast–in–situ

reinforced concrete were poured, over 30 kilometers of

railway tracks were laid.

At the moment of commissioning

and later, in the course of nearly twenty years, “Severyanka” remained the

largest blast furnace in the world. The giant blast furnace was put down into

the Guinness Book of Records. Today BF № 5 is the largest blast furnace in Europe . The working volume of BF № 5 is 5580 m3 . The

height of the furnace central assembly is 105 meters . To provide

the blast furnace operation 1 million and 700 thou. tons of coke, approximately

2 million tons of pellets and over 4 million tons of sinter are required

annually. The design furnace capacity is up to 4 million tons per year.

“Severyanka” satisfies nearly 50 % of the Cherepovets Steel Mill iron requirements.

During the period of operation

two major overhauls of the 1st category were carried out at the

“Severyanka” blast furnace in the course of which a great complex of updating

works was implemented: the hydraulic machines for the iron tapholes were

installed, the automatic process control system was renewed, the aspiration system

was revamped.

For the last major overhaul of

the 1st category Blast Furnace № 5 was stopped in June of 2006.

“Lengipromez” was entrusted to prepare the design documents again.

In the process of reconstruction in 2006 the blast

furnace shell was replaced partially while the cooling system was changed

completely. In addition to the iron the granulated slag is produced also at BF №

5 (it is produced at a special slag granulation plant from the blast furnace

waste – slag).

Basic indicators of BF№ 5 operation

| Working volume, m3 | 5580 |

| Oxygen enrichment, % | 28.84 |

| Hot blast temperature, ˚C | 1170 |

| Natural gas rate, m3/per 1 ton of hot metal | 102 |

| Top gas temperature, ˚C | 179 |

| Top gas pressure, atm gauge | 1.78 |

| Effective volume utilization factor | 0.46 |

| Output, t/daily | 12000 |

Blast Furnace “Severyanka”

Blast Furnace Shop № 5

Taphole drilling

Taphole drilling

Iron tapping at Blast Furnace № 5