UNION OF MYANMAR. IRON MAKING PLANT USING THE ROMELT PROCESS - Ленгипромез

Main menu:

UNION OF MYANMAR. IRON MAKING PLANT USING THE ROMELT PROCESS

PROGECTS > Foreign Projects

Panoramic view of the Plant site. Construction stage

“Zero” point of the future Plant in Myanmar

Basic indicators of the smelting process

Rate of oxygen enrichment of blast, % | 60 – 70 |

Furnace hourly capacity, t | 25.3 |

Hourly rate of burden materials consumption, t:

| 54 – 60 50 – 55 3 – 6 4 – 8 1.0 – 2.5 |

| Hourly slag yield, t | 20 – 25 |

Hourly energy carriers consumption, thou. Nm3/h - blast for blowing tuyeres, total including:

| 13 – 15 5 – 9 5 – 8 22 – 28 |

Hourly release of process gases from the furnace, thou. Nm3/h | 90 – 100 |

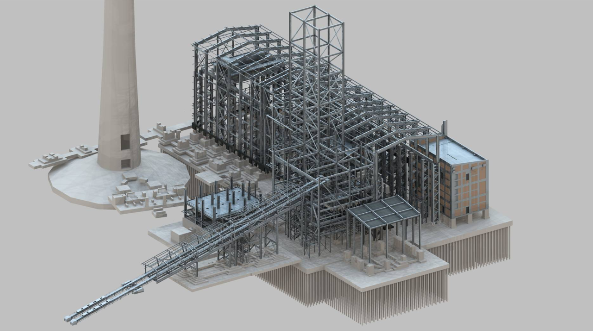

Three–dimensional simulation model of the Romelt Shop

Electronic audit of the working documents

Electronic audit of the working documents

Three–dimensional simulation model of the Romelt Shop

Electronic audit of the working documents

Electronic audit of the working documents

Erection of the Coal Preparation Unit structures

Erection of the Ore Sizing and Beneficiation Plant structures

The Iron

Making Plant Project in the Union of Myanmar is the first implementation on

industrial scale of the unique Russian technology – the ROMELT process – which

makes it possible to process the poor iron–bearing ore without any preliminary

beneficiation and to obtain a marketable product – the pig iron. As raw materials

for the pig iron production the local poor iron ore of the Pang Pet deposit

with the iron content of ore not exceeding 29 % and the power–generating coal

of the Kye Thee coalfield are to be used.

In addition

to the prime product – the pig iron – the ROMELT process allows to produce also

slag for commercial use (building of roads, erection of structures) and

electric power in the quantities sufficient to meet the own requirements of the

Plant and to transmit the power energy into the external electric power system

of the Union of Myanmar.

In

preparation of the design documents of the Iron Making Plant using the Russian

Romelt process in the Union of Myanmar with an output of 200,000 tons of pig iron

annually the following organizations have participated:

- “Lengipromez” Open JSC, the General Designer, has executed the comprehensive designing of the main units of the Plant, including designing of the service bins, the Romelt Shop, Pig Casting Machine, General Works Laboratory, Repair Shop, storage facilities, plant water supply facilities, Air Compressor Station, Gas Distribution Station of the external energy carriers systems.

- “Energoprojekt – Warszawa S. A.” – comprehensive designing of the Coal Preparation Unit of the Iron Making Plant.

- “Mekhanobr Engineering Co.” – comprehensive designing of the Ore Sizing and Beneficiation Plant.

- RUP “BelNIPIEnergoprom” – comprehensive designing of the Waste–Heat Recovery Electric Power Station (WHRPS).

- “Tyazhpromelektroprojekt Ltd” – designing of the Plant electric power supply system.

The ceremony devoted to the first stage of

commissioning of the Iron Making Plant to-be-constructed according to the innovative

Russian technology “Romelt” took place on October 21, 2015 in the Union of

Myanmar. Construction is being carried out within the contract signed by the

Myanmar Economic Corporation and the Joint Stock Company Foreign Economic

Association “Tyazhpromexport” included into the “Rostec” State Corporation.

The unique technology “Romelt” represents a

single–stage process of the iron smelting from various iron–bearing materials

by means of their liquid–phase reduction using the power–generating coal,

without use of coke and preliminary preparation of the iron–bearing burden

material. Actually, this is a noblastfurnace practice of iron production from

iron ore. For the first time this technology was tested at the Integrated Iron

and Steel Works in Lipetsk and in Kazakhstan

Construction of the Romelt Plant

Civil–engineering and erection works at the Pomelt Plant

Erection of the Pig Casting Machine building structures

Erection of the Pump House № 2 structures

Erection of the Oxygen Plant structures

Erection of the stock bins of raw materials structures

Framework structures of the casting bay and the Romelt furnace

Construction of the scaffold bridge of the burden delivery conveyer system into the Romelt furnace

Erection of the gas cleaning plant of the hot–metal desulphurization unit in the Romelt Shop